Automotive glues and adhesives play an important role in the auto industry. They are used to hold and glue parts/components onto the vehicle. These adhesives come in many forms, but finding the right one for your auto needs can be a difficult task. One way to find the right adhesive for your needs is to know the properties of the type of adhesive you are looking for.

There are a few things that you should look for when you select an adhesive. First, you should look for an adhesive that is durable, strong, and can hold a load. Next, you should look for an adhesive that is flexible to use. Finally, you should look for an adhesive that is easy to use and quick to dry.

Key Takeaways:

- Automotive adhesives are essential for creating durable seals and reducing vibration in various car components.

- These adhesives are designed to withstand extreme temperatures and prevent corrosion in metal parts.

- Selecting the right adhesive for the material—be it plastic, metal, or glass—is crucial for achieving the best results.

The Role of Automotive Adhesives in Vehicle Integrity

Automotive adhesives are used in a myriad of applications within a vehicle. They play a crucial role in bonding materials that are difficult to weld or screw together, such as plastic, vinyl, leather, and glass. The use of these adhesives is not just about sticking parts together; it's about creating a bond that can withstand the rigors of the road, including heat, cold, and moisture.

For instance, when it comes to battery terminals, which are susceptible to corrosion, the right sealers can provide a protective layer that prevents degradation. Similarly, in places where metal meets metal, the ideal adhesive will not only bond the surfaces but also prevent rust and corrosion by sealing out moisture.

Ensuring Durability and Performance

The durability of automotive adhesives is paramount. They must be able to withstand temperatures that a car typically experiences, from the heat of the engine to the freezing cold in winter climates. This is where products specifically designed to handle extreme conditions come into play, ensuring that the bonds remain secure and the seals intact.

In addition to temperature resistance, these adhesives are formulated to absorb and dampen vibrations. This is particularly important in areas of the car where metal parts are in close contact. By reducing vibration, adhesives can prevent wear and tear, contributing to a quieter and smoother ride.

Selecting the Right Adhesive for the Job

Choosing the right automotive adhesive is critical for achieving the best results. Each type of material—whether it's plastic, metal, or glass—has its own specific adhesive that's formulated to bond effectively. For example, adhesives used on exterior trim must be able to resist UV rays and weathering, while those used on interior components need to be safe for enclosed spaces and compatible with materials like leather and vinyl.

Moreover, the application process is just as important as the product itself. For optimal performance, surfaces must be clean and free of any contaminants. Some adhesives come in a tube for easy application, while others may require special tools or equipment to ensure an even and secure bond.

The Impact of Adhesives on Car Maintenance

Automotive adhesives are not only used during the manufacturing process but also play a significant role in car maintenance and repair. They can be used to reattach trim, fix leaks, or even patch up small holes. The versatility of these products makes them a must-have in any DIY mechanic's toolkit.

Furthermore, the use of adhesives can often be a more cost-effective solution compared to traditional repair methods. For example, instead of replacing an entire piece of trim, a strong adhesive can be used to reattach it, saving both time and money.

Summary

Automotive adhesives are essential for maintaining the structural integrity, performance, and appearance of a vehicle. They provide tight seals, reduce vibration, and protect against corrosion, ensuring that every part of the car, from the battery terminals to the exterior trim, remains in top condition. With the ability to bond a variety of materials and withstand extreme temperatures, these adhesives are ideal for a wide range of applications. By selecting the right product and applying it correctly, car owners and mechanics can achieve durable and reliable results that stand the test of time.

Can we help? We've done the research for you and found the Best Automotive Adhesive on Amazon. Every day, we read hundreds of reviews and try the highest-rated products we have on our list.

Best Automotive Adhesive - Reviews

The Best

Product information

When it comes to professional-grade products, this adhesive ranks at the top and is highly recommended by numerous Original Equipment Manufacturers (OEMs). It's a two-part epoxy adhesive, a feature that offers users the flexibility of an extended work time. If you're in a hurry, you can also rapidly cure it with heat. This adhesive's versatility is impressive, providing excellent adhesion on a wide range of plastic and metal substrates.

In addition to its strong bonding capabilities, it has multiple uses. It's perfect for bonding door skins, roof skins, quarter panels, box sides, and bumper covers. One unique feature of this adhesive is its glass bead technology. This technology helps protect against over-clamping and ensures a minimum bond line thickness is maintained. The package also includes two static mixing nozzles for ease of use. However, it's important to note that this product is intended for industrial or occupational use and is not available for consumer sale or use.

Almost as good as welding. Awesome product from 3M.

Can't return this product because it's classified as toxic.

Our Thoughts - This is a great adhesive, and stronghold, and is versatile. Being a

two-part epoxy make sure to read the instructions. Mix the two-part epoxy properly before use and will create a very strong mixture.

Very Good

Product information

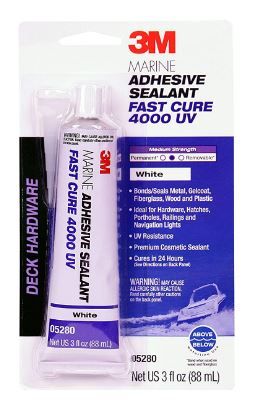

This one-part adhesive sealant is designed with efficiency in mind, typically curing in as little as 24 hours. This fast-acting solution allows you to get back on the water faster, minimizing downtime. It's perfect for a variety of applications both above and below the waterline, making it an ideal choice for sealing through-hull fittings, deck hardware, porthole frames, and screw holes.

Beyond its fast curing time, this adhesive sealant boasts a long-lasting formula. Its superior UV resistance ensures reliable performance over time, providing a durable solution for all your sealing needs. Adding to its versatility, the sealant can be painted immediately after application. Moreover, its medium-strength, semi-permanent nature allows for disassembly without damage, meaning bonded parts can be safely removed after prolonged use. As a one-component, moisture-curing, gap-filling sealant, it cures to form a firm, flexible, and waterproof seal on aluminum, wood, gel coat, and fiberglass. This makes it exceptionally well-suited for marine applications, whether above or below the waterline.

Another great product from a reputable company. It does a good job.

Packaging and delivery need improvement. Some customers complained of niggly issues that shouldn't have happened.

Our Thoughts - 3M adhesive sealant does what's supposed to do. Application is easy and has the potential for many uses. Remember it's an adhesive sealant, not a pure adhesive.

Good

Product information

J-B Weld Plasticbonder, in its distinctive black color, is a quick-setting, multipurpose, two-part urethane adhesive and gap-filling system. This product not only provides a strong and lasting bond to numerous plastic surfaces but also proves to be an excellent solution for various DIY plastic repairs, from filling dents to bumper repairs. One of its standout features is the innovative packaging - the adhesive now comes in a syringe that facilitates an easy 1:1 mix ratio. The syringe's unique design includes a resealable cap that prevents drying out and leakage, thereby allowing for multiple uses.

When it comes to cure and set time, the J-B Weld Plasticbonder is fast and efficient. After mixing the two-part formula with the included mixing tray and stir stick, the adhesive takes about 15 minutes to set and approximately 30 hours to cure. Notably, the set and cure color of this product is black. The strength of the J-B Weld Plasticbonder is impressive, boasting a tensile strength of 3770 PSI. It's versatile too, with surface applications that include thermoset and carbon fiber composites, thermoplastics, and coated metals, as well as plastic and PVC. It can also be used on concrete, ceramic and tile, fiberglass, and aluminum, making it a truly multi-purpose adhesive.

A very good product when used the way it should be. Make sure that the adhesive comes out of the syringe in equal parts, then mix it properly before applying.

Some users complained that it didn't do the job. But we don't understand why. Could it be that they used it like sticking paper together when they were in kindergarten?

Our Thoughts - There are hundreds if not thousands of types of plastic. However, there are two main categories thermoplastics and thermosets. These two are very different with different characteristics. One type of adhesive can't fix both.

Good

Product information

This product offers a flexible, waterproof bond that stands up to vibration, providing a reliable and durable solution for a myriad of applications. The adhesive is easy to brush and spread directly from the tube, offering users a time-saving convenience that makes any repair task less daunting. Notably, this adhesive exhibits resistance to oils, solvents, detergents, and temperature changes, making it an optimal choice for permanent repairs in various environments.

Suitable for bonding diverse surfaces, this adhesive works well with vinyl, metal, fabrics, and rubber. This versatility makes it a go-to product for many users. The adhesive was developed by 3M, a trusted brand known for its innovative products. It's particularly effective for bonding with weatherstripping around doors, trunks, T-tops, and sunroofs. Moreover, it provides excellent results when used around windows, ensuring a secure and lasting bond that withstands all weather conditions.

Works great! Plastic to plastic or plastic to rubber no problem.

Packaging and delivery need improvement. Some customers complained that the product was delivered already damaged. Tricky to use.

Our Thoughts - We think that many of the niggly issues are not from the product but the user. It's a good product from a very reputable company.

Best Value

About this item

This cold weld epoxy adhesive paste is specifically designed to bond various materials commonly found in automotive applications, including metal, rubber, fiberglass, and glass. It forms a robust bond that has the unique ability to flex, providing excellent resistance to impact and vibration. This characteristic makes it an ideal choice for use in environments where materials may be subjected to regular movement or varying levels of physical stress.

Another impressive feature of this adhesive is its wide range of continuous service temperatures, from -20 degrees Fahrenheit to +250 degrees Fahrenheit. This ensures reliable performance in both extreme cold and hot conditions. The adhesive offers a work time of 8 minutes, allowing ample time for application and adjustment. Afterward, it requires between 12 to 24 hours to fully cure at a standard room temperature of 75 degrees Fahrenheit. In addition to these features, the adhesive is also water-resistant, further enhancing its durability and versatility in various conditions and applications.

This is a great product for the right job.

Some customers complained that it didn't hold. Read the instructions before using.

Our Thoughts - Companies spend a lot of money on research and development before releasing a product to the market. We don't understand why users complain when they don't read instructions and then make a mess or expect miracles.

FAQs

Q: Can automotive adhesives replace welding or mechanical fasteners? A: Yes, in many cases, automotive adhesives can replace welding or mechanical fasteners. They offer a strong bond that can withstand the stresses of driving and are particularly useful for materials that are difficult to weld or screw together.

Q: Are there different types of adhesives for different materials? A: Absolutely. There are specific adhesives formulated for bonding different materials such as plastic, metal, glass, vinyl, and leather. It's important to choose the right adhesive for the material to ensure the best bond and performance. Also, battery terminals can be protected, as they are susceptible to vicious corrosion.

Q: How do I prepare a surface for adhesive application? A: To prepare a surface for adhesive application, it should be clean, dry, and free of any grease, oil, or dirt. Some adhesives may also require the surface to be slightly roughened to improve adhesion. Always follow the manufacturer's instructions for the best results.